Quality & Certifications

Our Commitment to Uncompromising Quality

Brinkman Precision keeps quality as the cornerstone of our entire operation. Our culture of continuous improvement is designed to meet and exceed the rigorous expectations of the aerospace industry. We are committed to delivering flawless components on time and on budget, in full accordance with all statutory, regulatory, and internal requirements of our AS9100D certified Quality Management System.

Quality Policy

Brinkman Precision, Inc. and Brinkman Industrial & Defense are committed to:

- Ensuring Product Safety

- Enhancing Customer Satisfaction

- Supporting the Organization’s Context & Strategic Direction

- Annual Management Review and setting of the Quality Objectives

- Assuring conformity to Customer and applicable Statutory and Regulatory requirements

- Fulfilling the effective application and Continual Improvement of the Quality Management System

Industry-Managed Certifications for Aerospace

AS9100D Certified

Our entire Quality Management System (QMS) is certified to the AS9100D standard, ensuring a robust framework for process control, risk management, and traceability throughout our entire organization.

NADCAP Accredited

We hold prestigious NADCAP (National Aerospace and Defense Contractors Accreditation Program) accreditations for our special processes, including Heat Treating and Nonconventional Machining. This accreditation is a testament to our technical excellence and procedural discipline.

Metrology Equipment

Verifying the precision of your components requires a significant investment in advanced metrology equipment. Our climate-controlled quality lab is equipped with state-of-the-art inspection technology, from Zeiss CMMs for complex 3D measurements to optical comparators and laser micrometers for non-contact gauging. This in-house capability allows us to validate every critical feature and deliver a component that is verifiably compliant with your specifications.

ZEISS Contura G2 Scanning CMM

Our flagship Coordinate Measuring Machines, the Zeiss Contura G2 automates the measurement of complex 3D components. With its high-speed scanning head and Calypso CAD software, it can quickly and accurately verify geometric dimensioning and tolerancing (GD&T) against your solid model, ensuring every critical feature is in perfect compliance.

- Working Range 30 x 40 x 20

- Glass scales with 8 millionths resolution, 2-micron accuracy (80 millionths)

- Articulating RD Probe receiver with 6-station probe changer

- Calypso CAD software

- Three (3) available

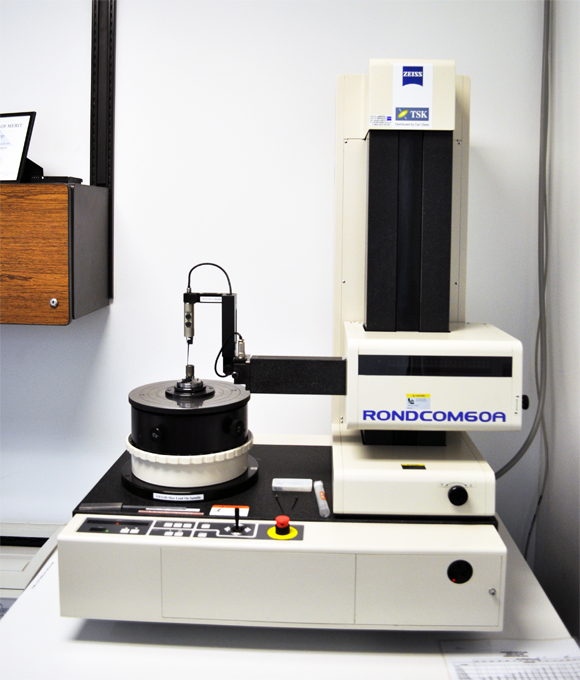

ZEISS/TSK Rondcom 60A Roundness Measuring Machine

Essential for high-performance rotating components, our Zeiss Rondcom machine measures roundness, cylindricity, and other form errors with millionths-of-an-inch accuracy. This capability is critical for verifying the precision of shafts, bearings, and other components where form is vital to function and longevity.

- Programmable 16″Dia. x 27″ Length Capacity

- 2 Millionths Roundness Accuracy

- Auto Tilt/Alignment

Pratt & Whitney Super Mic

This instrument serves as one of our primary in-house calibration standards. The Pratt & Whitney Super Mic provides absolute, direct-line measurement to ensure the gages and instruments used on our shop floor are calibrated to the highest degree of accuracy, guaranteeing measurement consistency across our entire operation.

- Bench Model 20 Millionths Digital Display/Resolution

- Used for gage calibration

Mahr Marsurf LD130

This advanced system allows us to precisely measure both the surface roughness and the contour profile of a component in a single pass. These parameters are critical for parts that require a specific texture for sealing, wear resistance, or aerodynamic performance. Its programmability ensures repeatable and accurate analysis of complex component profiles.

- Programmable surface roughness and contour machine

- Up to 130mm measurement length.

Optical Gaging Smart Scope Video Measuring System

The Smart Scope system provides automated, high-magnification, non-contact measurement. It is ideal for rapidly inspecting small, flexible, or complex components where traditional touch-probes are impractical. This technology allows us to verify critical edge profiles, hole diameters, and other fine features with exceptional accuracy.

- Programmable/Auto Inspect with 320 X Magnification

- 10 x 6 x 6 Travel Heidenhein Glass Scales with 10 millionths resolution

Omega TMM Exactus Lite Tool Presetter

A critical part of our process control, this tool presetter allows us to precisely measure our cutting tools offline. By setting and verifying tool geometries before they are loaded into a CNC machine, we significantly reduce setup times and eliminate the potential for error, ensuring the first part we machine is a perfect part.

Giddings & Lewis (Sheffield) Cordax Discovery Model D12 CNC/DCC Coordinate Measuring System

Measuring Range: 20 x 36 x 16 with measure max CAD Path

Single Touch Interface Software

Renishaw PH9 2 Axis Motorized Probe Head

Renishaw TP20 Touch Probe with Module Changer

Optical Gaging Smartscope Zip 250 Video Measuring System

Programmable/Auto Inspect with 320 X Magnification.

10 x 6 x 6 Travel Heidenhein Glass Scales with 10 millionths resolution

Two (2) Available

Optical Gaging Model QL-20 Contour Projector

Programmable/Auto Inspect 20” Screen

10-100x Magnification w/10 Millionths DRO’s

Three (3) Available

Marposs Electronic Sizing Display Columns

Analog & Digital Output

10 Millionths Resolution

Hand Held & Bench Mounted Sizing Rings for External/Internal Measurements

Sixteen (16) Available

Federal Air Gaging w/Digital Display Columns

Digital Output, 5 Millionths Resolution with Bench Mounted Sizing Stations for Internal Measurements

Six (6) Available

ZEISS Rondcom 40A Roundness Measuring Machine

6″ Diameter x 12″ Length Capacity

8 millionths Roundness Accuracy

Optical Gaging Model XL-14C Comparators

14” Screen

10-50x Magnification with DRO’s

Two (2) Available

Optical Gaging “Top Bench” Comparator

14” Screen

10-20x Magnification with DRO’s

Three (3) Available

Optical Gaging Model OQ-14B Comparator

Programmable 14” Screen

10-50x Magnification with DRO’s

Z-Mike 1200 Series Model 1201B Laser Micrometer

0-2” Capacity

20 Millionths Accuracy

Z-Mike 1200 Series Model 1202B Laser Micrometer

0-1” Capacity

20 Millionths Accuracy

Leica Microscopes w/fiber optic

Every Machine & work station

5x to 50x Magnification

Fifty-six (56) available

Leica Microscopes (QC/Inspection Area)

5x to 50x Magnification

Four (4) available

Federal Flatness Gage

20 Millionths Resolution Digital Indicator

18” x 18” Surface Plate

Leica 2-station Training Microscope

5x to 80x Magnification

Zeiss/TSK Surface (Roughness Tester) Model CM130A

Two (2) Available

Mitutoyo 13” .0001 Precision Height Stands

Two (2) available

Universal Model KK Concentricity Gages

Two (2) available