CNC Machining, Grinding &

Turning Equipment

Our commitment to quality and precision is reflected in our continuous investment in state-of-the-art manufacturing technology. This extensive in-house equipment list is the foundation of our capability, allowing us to maintain complete process control, hold exceptionally tight tolerances, and deliver the most complex aerospace components with confidence. We believe that using the world’s best equipment is the first step in producing the world’s best parts.

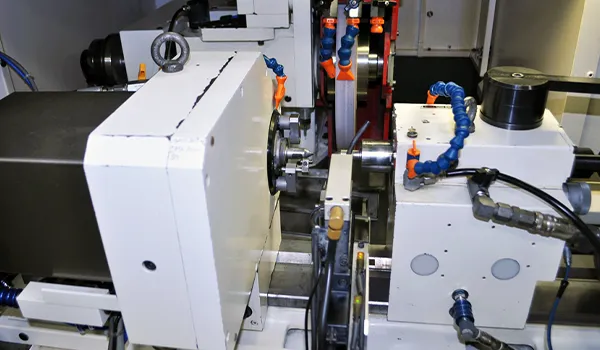

Automation

Our strategic investment in robotic and automated cells allows for unattended “lights-out” operation. This increases efficiency, ensures absolute process consistency, and provides a competitive advantage for high-volume production runs.

(1) Fanuc LR Mate & Control w/Robo Cart fully integrated into precision CNC Internal Grinding machine for un-attended operation.

(3) Universal Robots UR5e Automated deburring & finishing cells

(1) Universal Robots UR3e Automated deburring & finishing cell

Grinding Equipment

Our grinding department is a core strength, equipped with world-class machinery from Studer, Okamoto, and Sheffield. This technology allows us to achieve sub-micron tolerances and superior surface finishes that are critical for high-performance aerospace and medical components.

CNC O.D. Grinders

(2) Studer S33 CNC Cylindrical Grinder

9” Swing x 24” Between Centers, 20” x 3” Wheel Size w/Marposs Match Grinding System, Active/Passive Flagging, Fanuc 21i TB Control, Rotary Dresser, Auto Wheel Balancer.

(1) Studer S21 CNC Cylindrical Grinder

6” Swing x 16” Between Centers, 16” x 2” Wheel Size w/Marposs Match Grinding System, Active/Passive Flagging, Fanuc 21i TB Control, Programmable Dual Wheel Head, Rotary Dresser, Auto Wheel Balancer.

(3) Sheffield Model 20 Crush Form Grinders

5” Swing x 21” Between Centers, 16” x 3.5” Wheel Size, CNC servo profile wheel dresser, Sheffield Schuadt Cyberflex CNC position measuring, Auto Wheel Balancer.

Honing Machines

(2) Sunnen Honing Machines

Power Stroke & Gaging .060-6.00 Capacity.

(1) Sunnen EC3500 High Production Honing Machines

Fully Automatic w/Sizing .06-6.00 Capacity.

CNC Internal Grinders

(2) CNC Internal Grinder/Multi-Wheel Universal

4” Precision Chuck, (3) High Frequency Wheel Spindles, High Accuracy Workhead (6 millionths spindle), Glass Scales (10 millionths resolution), Rotary Dresser, 10,000 to 120,000 RPM High Frequency Wheel Spindles.

(1) Okamoto Universal CNC Internal Grinder w/Fanuc 18TC

8” OD x 8” Length w/High Resolution Feedback

10,000 to 60,000 RPM Wheel Speed, Rotary Dresser

(1) Okamoto IGM-15NCIII Internal Grinder

8”ID x 5” Length w/High Resolution Feedback

10,000 to 60,000 RPM High Frequency Wheel Speed, Rotary Dresser.

Surface Grinders

(1) Okamoto DNC Model 12-24 DXNC Surface Grinder

12” x 24” Table, 7.5 H.P. 14” x 2” Wheel Size, Auto Wheel Balancer.

(1) Okamoto DNC Model 8-20 DXNC Surface Grinder

8” x 20” Table, 5 H.P. 8” x 1-1/2” Wheel Size.

Turning Equipment

Our extensive lineup of CNC turning centers from Mori-Seiki, Mazak, and Hardinge enables us to produce highly complex cylindrical components. With multi-axis, live-tooling, and Swiss-style sliding headstock capabilities, we can machine intricate parts in a single, efficient operation.

CNC Turning Centers

(2) Mori-Seiki ZT1500Y Multi-axis CNC Lathes w/Y-axis live tooling

6 & 8″Chucks/Collet Chucks, 8″ Max Turn Dia., 12″ Max Turn Length

2 & 2.5″ Hydrodynamic Magazine Barfeeder, 24-tools w/VDI Turrets, Auto Tool Probing, 2000 PSI Coolant System

(2) Mori-Seiki NL2000 2-axis CNC Lathes

8” Chuck, 8” Max Turn Dia., 20”Max Turn Length w/Programmable Tailstock

12/16 Position Turret, 2” x 4ft. Barfeed, Tool Probe, 1000 PSI Coolant

(2) Mori-Seiki NL1500Y CNC Lathes w/Y-axis Live Tooling

6” Chuck 6”Max Turn Dia., 20”Max Turn Length w/Programmable Tailstock

12 Position Turret, 2” x 4ft. Barfeed, Tool Probe, 1000 PSI Coolant

(1) Mori-Seiki DT 2050 CNC Lathe

8” Chuck, 13.3” Max Turn Diameter , 20.8” Max Turn Length w/ programmable tailstock, 12 Position Turret 2.5” Bar Capacity, Tool Probe, 1000 PSI Coolant

(1) Mori-Seiki NL1500YS CNC Lathe w/Y-axis live tooling and Sub-Spindle

6” Chucks/Collet Chucks, 6”Max Turn Dia., 20”Max Turn Length w/sub-spindle

12 Position Turret w/back working tool blocks, 2” x 4ft. Barfeed, Tool Probe, 1000 PSI Coolant

(1) Mori-Seiki 1530 2-axis CNC Lathe (chucker)

6” Chuck/Collet Chuck, 6” Max Turn Dia., 12”Max Turn Length

12 Position Turret and Tool Probe

(1) Mori-Seiki NLX2000 CNC Lathe w/Y-axis live tooling

14” Max Turn Dia., 20” Max Turn Length, 2.5” Max Bar Dia.

(1) Mori-Seiki NLX2500 CNC Lathe w/Y-axis live tooling

18” Max Turn Dia., 49” Max Turn Length, 3.5” Max Bar Dia.

(1) Okuma LT2000-EX-2T2MY Twin Turret CNC Lathe

8.36” Max. Turn. Dia., 29.5” Max. Turn Length

(2) 16 Station Turrets w/ Live Tooling and Y-Axis

(1) Hardinge T51L Lathe with Live Tooling

8” Chuck, 13.5” Max Turn Dia., 22.8” Max Turn Length

Programmable Tailstock

16C & 20C Collet Chucks 2 ½° Indexing on Spindle, High Pressure Coolant

(2) Hardinge T51 Lathe

8” Chuck, 13.5” Max Turn Dia., 22.8” Max Turn Length

Programmable Tailstock. 16C & 20C Collet Chucks, High Pressure Coolant

(2) Doosan 2600SY II

10” Chuck x 15” Max turning diameter, x 30” Max Turn Length

Twin Turret w/ 5K RPM Live Tools & Y Axis

4K RPM Main Spindle, 6K RPM on Sub

(1) Doosan Lynx 220A 2-Axis Lathe

6” Chuck x 8”Max Turn Dia., x 19” Max Turn Length

Programmable Quill Tailstock

5C Collet Chuck, 6000 RPM, High Pressure Coolant

(1) Doosan Lynx 2100MA

6” Chuck x 8” Max Turning Diameter, x 12” Max Turn Length

12-Station Turret w/Live Tools & Programmable Tailstock

5C Collet Chuck, 6000 RPM, High Pressure Coolant

(1) Doosan Lynx 2100

6” Chuck x 8” Max turning diameter, x 12” Max Turn Length

12-Station Turret and Programmable Tailstock

5C Collet Chuck, 6000 RPM, High Pressure Coolant

(1) Hardinge SP27 Super Precision CNC Gang Lathe

10 millionths control resolution with 4” Air Chuck

for Precision Finishing Operations

(1) Hardinge CHNC Super Precision CNC Turret Lathe

10 Millionths Control Resolution, 5C Spindle Nose and 4” Air Chuck

for Precision Machining/Finishing Operations

(1) Hardinge CNC Gang Tool Lathe

CNC Sliding Headstock (Swiss CNC Lathes)

(1) Citizen A20 7-Axis Swiss Lathe(sliding headstock)

20mm (.790) Hydrodynamic Barfeed Capacity, Max Part Length 3.94”

10,000 RPM Main Spindle, 8000 RPM Back Spindle, Full C-axis (both spindles)

21 Tools, Cross & Live Backworking w/Simultaneous turn & End Working Functions. 1000 PSI High Pressure Coolant

(1) Citizen L20 7-Axis Swiss Lathe(sliding headstock)

20mm (.790) Hydrodynamic Barfeed Capacity, Max Turn Length 7-3/4”

10,000 RPM Main Spindle, 8000 RPM Back Spindle, Full C-Axis (both spindles)

21 Tools, Cross & Live Backworking w/Simultaneous Turn & End Working Functions. 1000 PSI High Pressure Coolant

(1) Citizen M32Y 14-Axis Swiss Lathe(sliding headstock w/turret)

32mm (1-1/4”) Hydrodamic Barfeed Capacity, Max Turn Length 12-1/2”

8000 RPM Main Spindle, 7000 RPM Back Spindle, Full C-Axis (both spindles)

24-Position, 12-station Turret w/Y-axis, (12) Cross & Live Backworking w/Simultaneous Turn & End Working Functions. 1000 PSI High Pressure Coolant

Lathes (Manual)

(1) Victor 1440G Lathe

6” and 8” Chucks, 7-3/4” Max Turn Diameter, 14” Max Turn Length with Sub Spindle, 1000psi coolant system

(10) Overbeck “Twister”

Polishing/De-burring Lathes

(5) Hardinge

DSM-59 Production Lathes (cont)

(1) LeBlond-Makino

12” x 30” Engine Lathes

Milling Equipment

Featuring high-speed vertical machining centers from Mori-Seiki, Makino, and Haas, our milling department is built for precision and versatility. With 4th and 5th-axis capabilities, we can handle complex contours and features required for sophisticated aerospace components.

(1) Bridgeport Vertical Mill with DRO

(3) Makino DA300 5 Axis with 40 Station Pallet System

118 Tool Automatic Tool Changer

(1) Mori-Seiki NV5000B Vertical Machining Center

Axis Travel X=40” Y=20” Z=22” 30 HP, 14,000 RPM Spindle

Positioning Accuracy +/-.0002 Repeatability +/-.0001

4th/5th Axis Indexing/Rotary Trunnion Table w/ 6” Face Plate

Tool & Part Probing, 32 Station Tool Changer

1000 PSI Chip Blaster Coolant System

(2) Makino F5 Vertical Machining Center

Vertical 3 Axis CNC Milling Machine

Axis Travel X= 35.4” Y= 19.7” Z=17.7” 20,000 RPM Spindle

Positioning Accuracy +/- 0.000060″

Repeatability +/- 0.000040”

30 Station Automatic Tool Changer

(2) DMG Mori DuraVertical 5100 Machining Center

Axis Travel X=41.3” Y=20.9” Z= 20.1”, 10,000 RPM Spindle

4th Axis Indexer, 30 Tools Automatic Tool Changer

(1) HAAS VF-3 Vertical Machining Center

Axis Travel X=40” Y=20” Z=25” – 20 HP, 10,000 RPM Spindle

(1) Doosan DVF5000 5 Axis with 12 Station Pallet System

60 Tool Automatic Tool Changer

(1) DMG Mori DMU50 5 Axis with 10 Pallet System

60 Tool Automatic Tool Changer

(1) DMG Mori DMU50 5 Axis Standalone

60 Tool Automatic Tool Changer

(1) DMG Mori NVX 5100 Vertical Machining Center

Axis Travel X=41.3” Y=20.9” Z= 20.1”, 10,000 RPM Spindle

4th, 5th Axis Indexer, 30 Tools Automatic Tool Changer

(1) DMG Mori NHX 4000 Horizontal Machining Center

6 Pallet Stations

60 Tool Automatic Tool Changer

Special Process Equipment

By keeping critical special processes like NADCAP-accredited Heat Treating and CNC Wire EDM in-house, we reduce reliance on outside vendors, shorten lead times, and maintain full control over the quality of your components from start to finish.

Heat Treat Department

(1) Abar Ipsen Vacuum Furnace. Turbo-Treater 2-Bar

Computer Controlled Heat Treat Cycles & Data Recording

12 Cubic Ft.

(1) 300° Below Model 925 Deep Cryogenic Processor

-100° to -300° F, 20 Cu. Ft. Capacity

(1) Beavermatic 1350° Controlled Atmosphere Tempering Furnace

CNC WIRE EDM (submerged)

(1) Makino U32i Wire EDM

.003/.012 Wire Size. Working Range:18 x 20 x 9 w/ Rotary head

(1) Makino DUO43 Wire EDM

.003/.012 Wire Size. Working Range:18 x 20 x 9

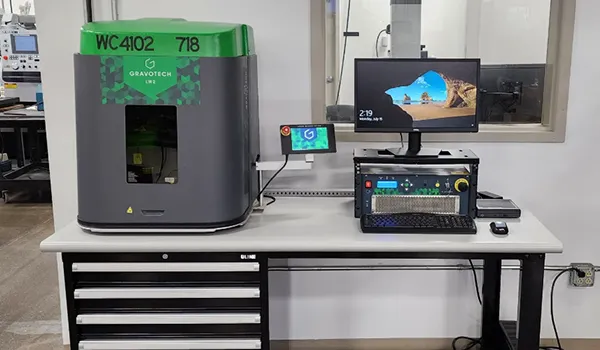

Laser Marking Equipment

(1) Rofin Laser Powerline Air25 w/ Visual Marking Controller

(1) Gravotech LW2 30 Watt Fiber Laser Station

CNC 4th/5th Axis EDM Hole Drill

(1) Belmont SY-CNC3040T CNC EDM Production Hole Drill

.006”-.118” Dia. 10 x 14 Table Travel w/ 20-Station Electrode Changer

EDM Hole Drills

(1) Astec A33M/P3 High Speed Production EDM Hole Drill w/auto 5C Indexer

.006”-.118”Dia. 15 x 15 Table Travel

(4) Astec A22M/P2 High Speed Production EDM Hole Drill w/auto 5C Indexer

.006”-.118” Dia. Capacity. 8 x 8 Table Travel

Finishing & support equipment

Engineering & Programming (CAD/CAM)

To provide a truly comprehensive service, we maintain a full suite of in-house finishing and support equipment. From precision deburring and sandblasting to automated production sawing, these capabilities allow us to control every step of the process, ensuring your components are delivered clean, finished, and ready for assembly.

(1) Behringer Fully Automatic Production Band Saw

10” x 10” Capacity, 12 ft. bar lengths

(1) Primary/Secondary Back-up Air Compressors w/ Dryers

(1) Sandblasting Equipment for Production Finishing

(1) Centrifugal Disc Finishing (Dual Bowl) w/ Allen Bradley Batch Controller for deburring/finishing of smaller precision parts.

(3) Micro-Blast Cabinets for Precision Finishing/Deburring of fine microscopic break edge details.

Our engineering team leverages industry-leading CAD/CAM software, including SolidWorks and MasterCam, to ensure seamless integration with your design files. This allows us to program complex toolpaths, optimize for manufacturability (DFM), and translate your exact digital specifications into a precisely machined physical component.

HP Pentium Workstations

SolidWorks

Cadkey 2000

MasterCam

Cimco DNC

Cimco MDC

Ready to Leverage Our Technology?

This investment in premier equipment demonstrates our readiness to tackle the most demanding manufacturing challenges. If your project requires the highest level of precision and process control, our facility is equipped to deliver. Contact our engineering team to discuss your component specifications.